Garrattfan's Modelrailroading Pages

NS class 5000

Chassis construction preparation

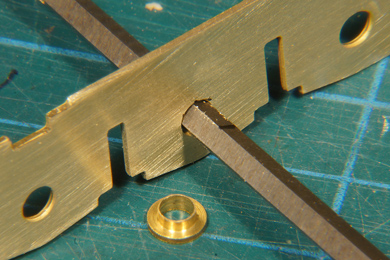

The first cut, I declare this project for STARTED!! |

|

Generally it is recommended to cut etched parts out of a fret by cutting the tabs with a sharp knife on a hard surface. You will see me do that later in this build. This applies to the most common form of etched frets: 0.5 mm sheet with half-etched tabs, so 0.25 mm. This fret however is no less than 0.9 mm thick and the tabs are not half-etched. I did not even attempt cutting them with a knife but got out my jeweller's saw which made short work of the strong tabs. The discolouration of the brass sheet show its age.

|

|

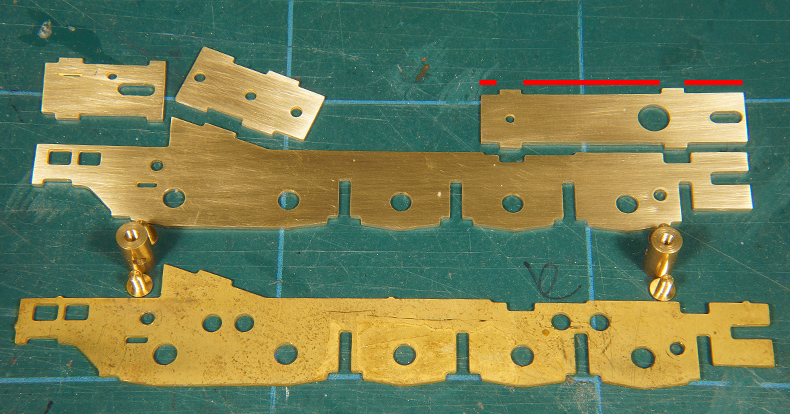

A trail assembly to get a feel how every ting goes together. |

|

All but one cleaned and de-cusped. The right hand frame plate was left unchanged to show the huge impact of a bit of sanding of the sides on 1200 emery paper. |

|

I filed all cusps off all around. Technically it is not necessary but I hate to see cusps, remainders of the etching process. It is sloppy work of lazy builders. So I removed them. I also did this on all sides of the spacers. This was a bit of a miscalculation. The cusps on the recessed sides (red lines) have been calculated into the width of the etched spacers. A little bit of filing would have made them fit perfectly but filing the cusps away completely to obtain a a flat side was a bit too much. The spacers now have a bit of play loosing much of their function as, well, spacer. I will have to adjust the frame carefully before soldering.

|

|

|

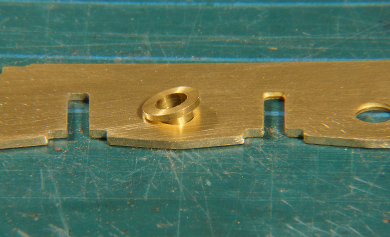

A trial fit of the middle axle bearing. I did not fit, as expected. Well designed kit have such holes a bit undersized. Etching is an inaccurate process and it is better to have them bit undersize than too big. It is up to modeller to open them up with a bit of reaming to get a perfect fit. |

|

Much to my surprise I needed only a few turns to get a perfect press-fit of the bearing. I marked the reamer so I could quickly replicate the width of the bearing hole on the opposite side. I will give three bearings an accurate position without play beforehand:

So the holes of these bearings are reamed to press-fit the bearing. They will also be soldered straight away into the frame plates.

The remaining seven holes were reamed more liberally giving all other bearings a play of say 0.5 mm.

◄ Like so

The hows and why of that will be explained during the actual construction of the chassis. |

|

|

| Before I could advance into that stage I needed to make final decisions about the drive train first. | |

Sign my

GuestBook